About MX Nylon

Characteristics

MX Nylon containers and packages will solve your issues!

- High gas barrier and chemical resistance material

- MX Nylon has a high gas barrier property against oxygen (O2) and carbon dioxide (CO2) and high chemical resistance.

- Ecofriendly material

- Ecofriendly MX Nylon contributes to a sustainable society!

WASTE REDUCTION

REDUCTION

EMISSIONS

Applications

Food / Beverage packages

- Needs

- Extends the shelf life and maintains the taste of food and beverage for a long time

Solution

-

MX Nylon extends the shelf life by 2.4 times with its high gas barrier property

MX Nylon is our unique material with high gas barrier property.

Using it as a packaging material for food and beverage will prevent the deterioration of taste and quality and extend the shelf life.

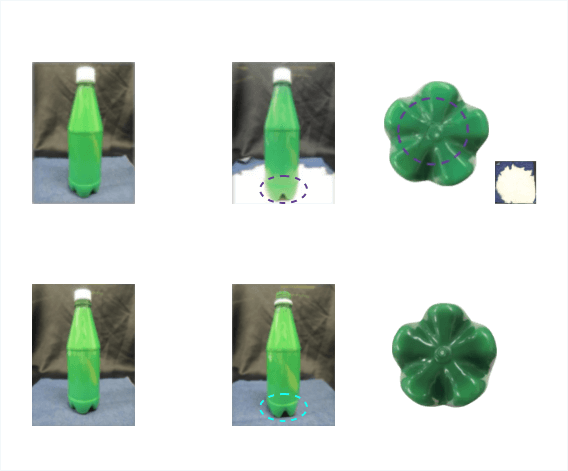

The best example is a multilayer PET bottle that is manufactured by combining MX Nylon with a PET material.

Compared with a conventional PET bottle, it extends the retention period of CO2 by “2.4 times”.※1 PET : Polyethylene Terephthalate

Case 1

-

A package that can extend the shelf life of food and beverage

It also allows you to store the food and beverage for a long time and is beneficial to the consumers.

-

- <MX Nylon can be used for the packages of various food and beverage>

- MX Nylon can be used not only for PET bottles but also for flexible containers (such as films and pouches), rigid containers (such as cups and trays). Consequently, it extends the storage period of various food and beverage products, such as tea and drinking water in addition to foods treated with retort or boiling sterilization.

-

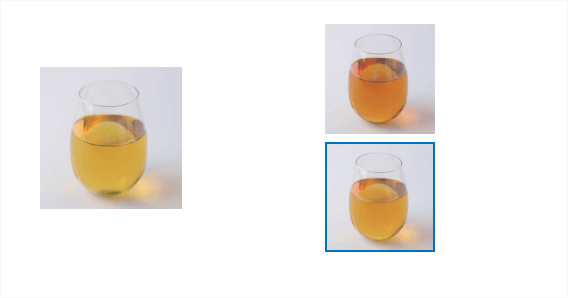

- PET bottle (multilayer, blend monolayer)

-

It is widely used as PET bottles for tea, carbonated soft drink (CSD), drinking water, beer, and wine to extend their shelf life. Furthermore, it enables PET bottles to preserve the quality of the beverage for a long time, even in a high-temperature and humidity environment where the quality deteriorates quickly.

-

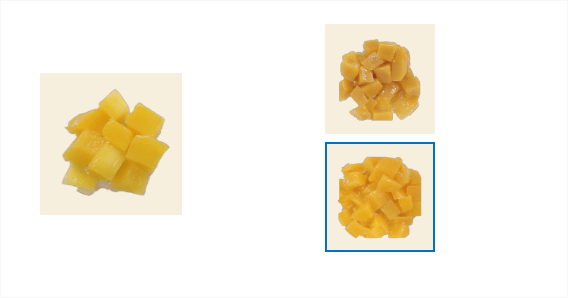

- Film (multilayer with PA※2/PO※3(PE※4, PP※5), PET blended with PA)

-

It is widely used in packaging foods that may change in taste and quality due to heating and oxidation. When it is combined with the materials of conventional products, it enhances the high barrier property and resistance to retort and boiling, thus making the film more difficult to tear.

※2PA: Polyamide,※3PO: Polyolefin,※4PE: Polyethylene,※5PP: Polypropylene

-

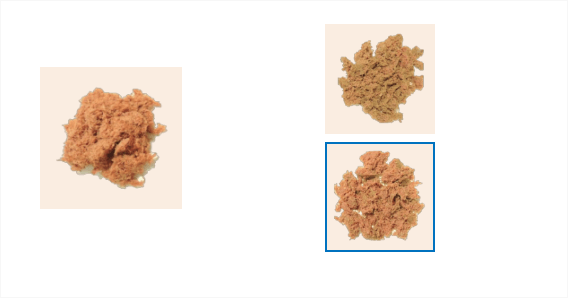

- PP multilayer container

-

Multilayer containers that combine MX Nylon and PP are widely used in packaging of food, such as fruits and pet foods. It can help containers to maintain high barrier property, even after treatment with retort or boiling sterilization.

Case 2

-

A PET bottle that preserves the good taste of drinking water for a longer time

The consumption of PET-bottled drinking water keeps growing world-wide.

As the demand for PET bottles keeps growing in households as well as in hotels and restaurants, the demand for containers that preserve the taste of drinking water for a long time is also increasing.

PET bottles blended with MX Nylon make it possible to drink good tasting water for a long time.

PET bottle containers sometimes contain a small amount of acetaldehyde (AA) and formaldehyde (FA), which are said to deteriorate the taste of the drinking water when they leak and dissolve out of the container with time.

When 0.5% MX Nylon is mixed into PET material, it reduces AA by 23% and FA to an undetectable level, thus preserving the good taste for a long time.

Case 3

-

A light-weight PET bottle that is ecofriendly and extends shelf life

Light-weight PET bottles have many advantages, such as the reductions of transportation cost, plastics used, and CO2 emission during transportation.

However, simply making the PET monolayer bottles lighter decreases the gas barrier property and shortens the shelf life.

MX Nylon resolves such dilemma.

PET/MX Nylon blend bottles are lighter while maintaining shelf life.

PET/MX Nylon multilayer bottles are thinner and light-weight but still ensure a longer shelf life.

Packages for personal care products and chemicals

- Needs

- Packages that are tough and long-lasting; Safe containers for chemicals

Solution

-

MX Nylon with higher chemical resistance makes the containers last 4 times longer than conventional containers!

When you choose plastics as a material for containers, substituting glass and metals, you would be most concerned about their durability.

In case of PET monolayer bottles, the chemicals inside could leak within 3 months.

Mixing with MX Nylon, which yields bottles that can safely store for 12 months, is possible.

Case 1

-

A package suitable for a long-term storage without chemical erosion or odor emission

It is widely used as containers for chemicals, personal care products, bleach and ink. It prevents the leakage of its content by using MX Nylon.

In an experiment using highly volatile toluene, a PE bottle mixed with MX Nylon prevented toluene permeation by approximately 16 times more than a PE bottle without MX Nylon.

It can also protect from unpleasant and harmful odors by its high gas barrier capability.Solvent Transmission rate (g/bottle/day) HDPE monolayer MX Nylon blend Toluene 2.65 0.16 Xylene 1.96 0.14 Limonene 0.92 0.05

Characteristics and usage of packages

-

- PET bottle

- PET bottles for bleach, ink, dental rinse, and perfumes make it possible to store them for a long time without affecting the product quality.

-

- Polyolefin bottle

- Polyolefin bottles for pesticides, agrichemicals, and organic solvents make it possible to store them for a long time through its high chemical resistance.

-

- Film

- Film is used for various personal care products to maintain the product quality. Moreover, it prevents the permeation of smells.

Physical Properties

| Item | Test Method | Unit | MX Nylon | |

|---|---|---|---|---|

| 6000 series | 7000 series | |||

| Melting Point | ISO3146 | ℃ | 237 | 229 |

| Glass Transition Temperature | ℃ | 85 | 92 | |

| Density | ISO1183 | g/cm3 | 1.21 | 1.21 |

| Water Absorption | MGC method | % | 5.8 | 5.8 |

| Tensile Strength | ISO527-1 | MPa | 112 | 112 |

| Tensile Modulus | GPa | 4.9 | 4.9 | |

-

- Superior Gas Barrier Properties

- MX Nylon not only possesses excellent O2 barrier properties but it can also function as a barrier to other gases such as CO2. The barrier properties also show less deterioration in high humidity environments. In particular, MX Nylon has the highest O2 barrier among all commercially available polyamides and is commonly used for food and beverage packages.

-

- Suitable Processing Temperature for Various Applications

- The melting point of MX Nylon is 237℃. The processing temperature of MX Nylon matches well with the temperature range for molding other materials. This means you can use MX Nylon in combination with PET, PP or PE to achieve co-injection molding and co-extrusion molding to produce laminated containers, and packaging sheets.

Safety and Hygiene

MX Nylon standard grades comply with the following food safety law regulations:

- Japan

-

Passed the standards set by the Ministry of Welfare Notice No.370 and listed in positive list for food contact material.

Complies with the voluntary standards of the Polyolefin Safety Council and approved by and registered with the Council.

Existing Chemical Substance No. is 7-387(poly m-xyleneadipamide).

- US

- Approved as registered under FDA 21CFR §177.1500, (b), (10.1), §177.1630,(e), (4) (v), §177.1390, (c), (1), (I), (e) and FCN #1841.

- EU

- Listed on the Commission Regulation (EU) No 10/2011 as monomers in ANNEX I.

- China

- GB 4806.6-2016

※ The CAS Registry No. of MX Nylon is 25718-70-1 (Hexanedioic acid, polymer with 1,3-benzendimethanamine).

※ If you have any question about other country’s regulatory status or you need more information, please contact us.

Toward Sustainability

-

Impact on environment by food waste, increased plastic use, and increased CO2 emission are much talked about in recent years. Toward Sustainability has been mentioned for some time now, and it is acceptable to say that a corporation cannot carry on its business without paying attention to it. We keep the strong commitment in mind toward responsible consumption and production, a sustainable development goal, when we engage ourselves in developing materials.

-

MX Nylon is an ecofriendly material.

Using MX Nylon with low O2 and CO2 permeability in the packages of food and beverage will lead to shelf life extension and food waste reduction.

In addition, containers using MX Nylon can be made light-weight, which will reduce the usage of plastic and emission of CO2 during transportation.

-

- Safer containers with improved gas barrier property:

- Achieves food loss and waste reduction by longer shelf life.

FOOD LOSS AND

WASTE REDUCTION -

- Thinner containers that still maintain gas barrier property:

- Reduces the use of plastic.

WASTE PLASTIC

REDUCTION -

- Lighter containers:

- Reduces CO2 emission by improved fuel efficiency in transportation.

LESS CO2

EMISSIONS

MX Nylon, which is ecofriendly,

leads to a sustainable society.